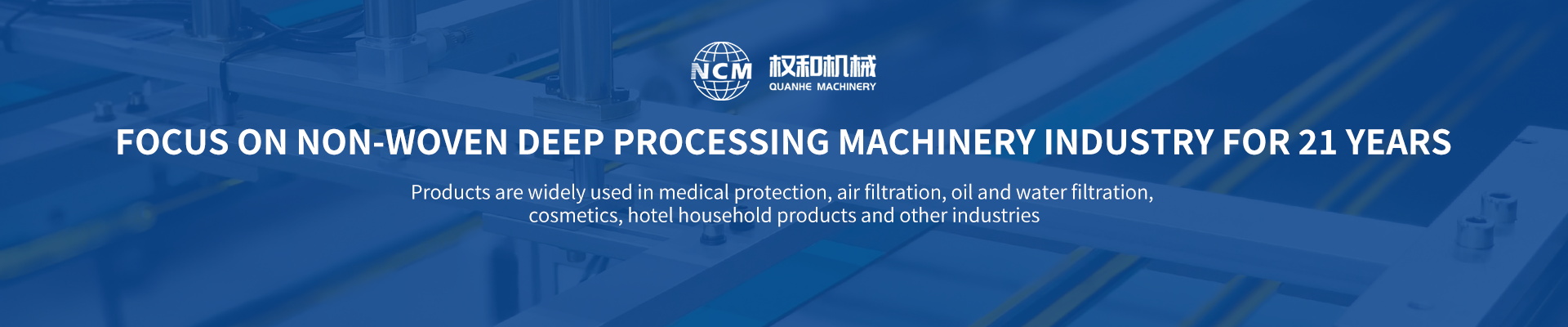

NC-7021 First-effect ladder bag machine (double-layer or six-layer compound)

- 发布日期:2024-04-25

- 访问量:1104 次

- 产品介绍

- 视频

- 相关产品

Functional parameters of trapezoidal bag machine:

1. Production capacity: 3-10 tablets/minute (related to product length, cloth thickness and melting point)

2. There are 6 material racks with 3-inch paper tubes, which are universal without paper tubes. According to the characteristics of fluffy and thick materials and less meters per roll, 6 sets of servo rectification devices are installed (each layer of materials is automatically rectified by servo, and the materials do not deviate when the equipment is running, thus reducing labor and material loss).

3. The minimum bag depth is 350mm, the maximum bag depth is 720mm, and 0-3 passes of grid welding are optional, and the middle/bottom of welding bag is optional.

4. The main engine uses 6 sets of servo motors and 1 set of stepping motors (Taiwan Province Delta servo motors and Lei Sai stepping motors, of which 3 sets are absolute servo, so it is not necessary to find the origin when starting, and the stop angle data is automatically saved when power is off, which can reduce the adjustment time and material loss).

5. Japanese Mitsubishi P.L.C (FX5U series) is used for program control, and the man-machine interface uses Xinjie 10-inch touch screen.

6. Cylinder (Taiwan Province Yadeke)

7. Ultrasonic wave: 6 sets of specific 15KHZ high power.

8. The frame is made of 3.0 thick aluminum profiles, which is solid and beautiful.

9. The main parameters of the equipment (such as barrier welding and edge melting welding) are automatically calculated by the system. The touch screen is intuitive and simple to operate. The man-machine interface can save 100 sets of formula parameters, and the adjusted parameters can be saved for next call, thus further greatly reducing the material loss.

10. Various sizes of bags can be adjusted, and the angle can be adjusted in a wide range from -10 degrees to+10 degrees.

11. The equipment is stable, the failure rate is low, and it is simple and easy to operate (only 1 ~ 2 people are needed to operate).

Machine features:

High stability, easy operation and excellent performance.

3MM aluminum alloy machine structure, beautiful and solid.

Servo automatic deviation correction control of material rack

The servo motor of the main engine Delta has stable control, high precision and accuracy.

15KHZ high-power ultrasound with strong output.

Mitsubishi FX5U High Performance PLC Program Control

Machine specifications:

Machine size: 7500(L)×1300(W)×1850(H)mm(2-story material rack)

Machine size: 10000(L)×1300(W)×1850(H)mm(6-story shelf)

Voltage: 380V,3P.

Capacity: 3-10PCS/min

Power consumption: 8Kw

Air pressure: 0.5~0.8MPa

-

NC-7021 First-effect ladder bag machine (double-layer or six-layer compound)

NC-1000 Trapezoidal lining bag welding machine

NC-1001 Trapezoidal lining bag making machine

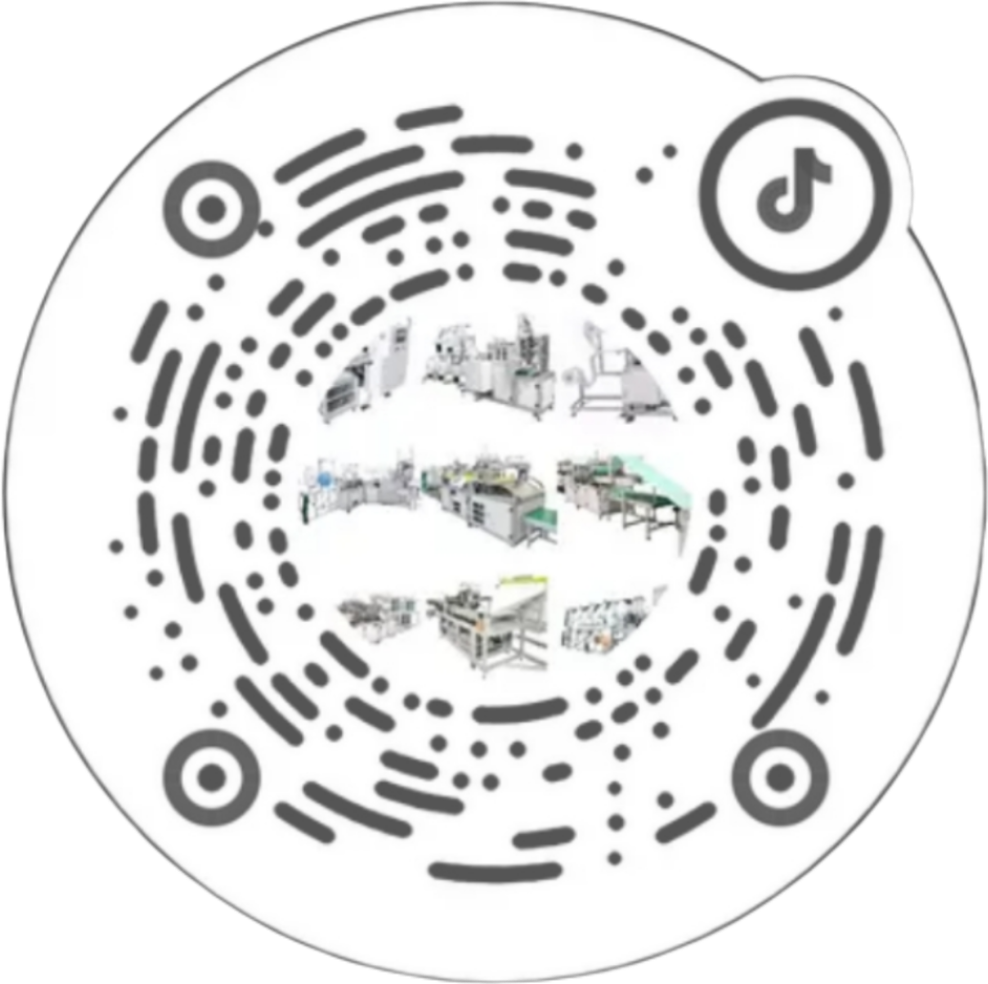

NC-90 ultrasonic quilting machine/ultrasonic bonding machine

NC-7020 intermediate dust bag manufacturing machine

NC-7020 Medium-effect chemical fiber bag one-meter widening machine

NC-6000 Ultrasonic Edge Sealing Welding Machine (lace machine)

NC-8020 Folding type primary effect filter bag machine